Prefabricated Building Components

Prefabricated buildings consist of various components, each serving a specific function in the overall structure. Understanding these components is crucial for designing, manufacturing, and assembling prefabricated buildings effectively. Here are the primary prefabricated building components:

Structural Elements

Structural elements form the framework of the building and provide support and stability. These components are typically fabricated off-site and include columns, beams, trusses, and other load-bearing elements. In prefabricated construction, structural elements are often made from materials such as steel, concrete, or timber. Prefabricated structural elements are engineered to meet specific design requirements and are manufactured with precision to ensure structural integrity and durability.

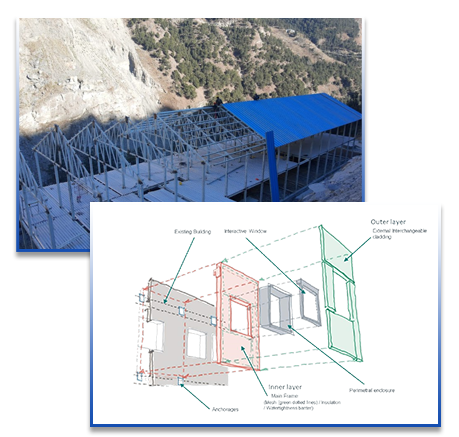

Facade Elements

Facade elements define the exterior appearance and envelope of the building, contributing to its aesthetics, weatherproofing, and energy efficiency. These components are manufactured off-site and include wall panels, window assemblies, cladding systems, and architectural features. Prefabricated facade elements offer advantages such as faster installation, improved quality control, and enhanced design flexibility. They can be customized to meet architectural specifications and are available in a variety of materials, finishes, and colors to achieve desired aesthetic outcomes.

Interior Finishes

By incorporating prefabricated building components into construction projects, stakeholders can realize benefits such as cost savings, time efficiency, improved quality control, and enhanced design flexibility. Prefabricated components are engineered and manufactured with precision to meet stringent performance standards, resulting in buildings that are durable, sustainable, and aesthetically pleasing.